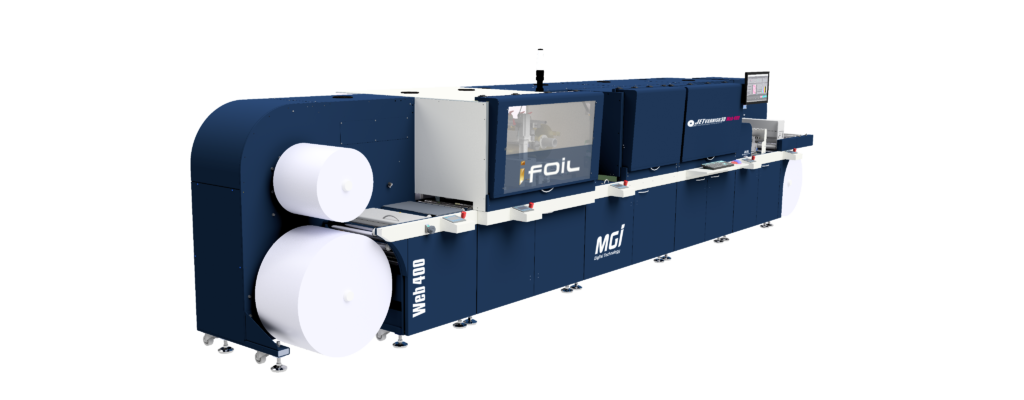

JETvarnish 3D Web 400

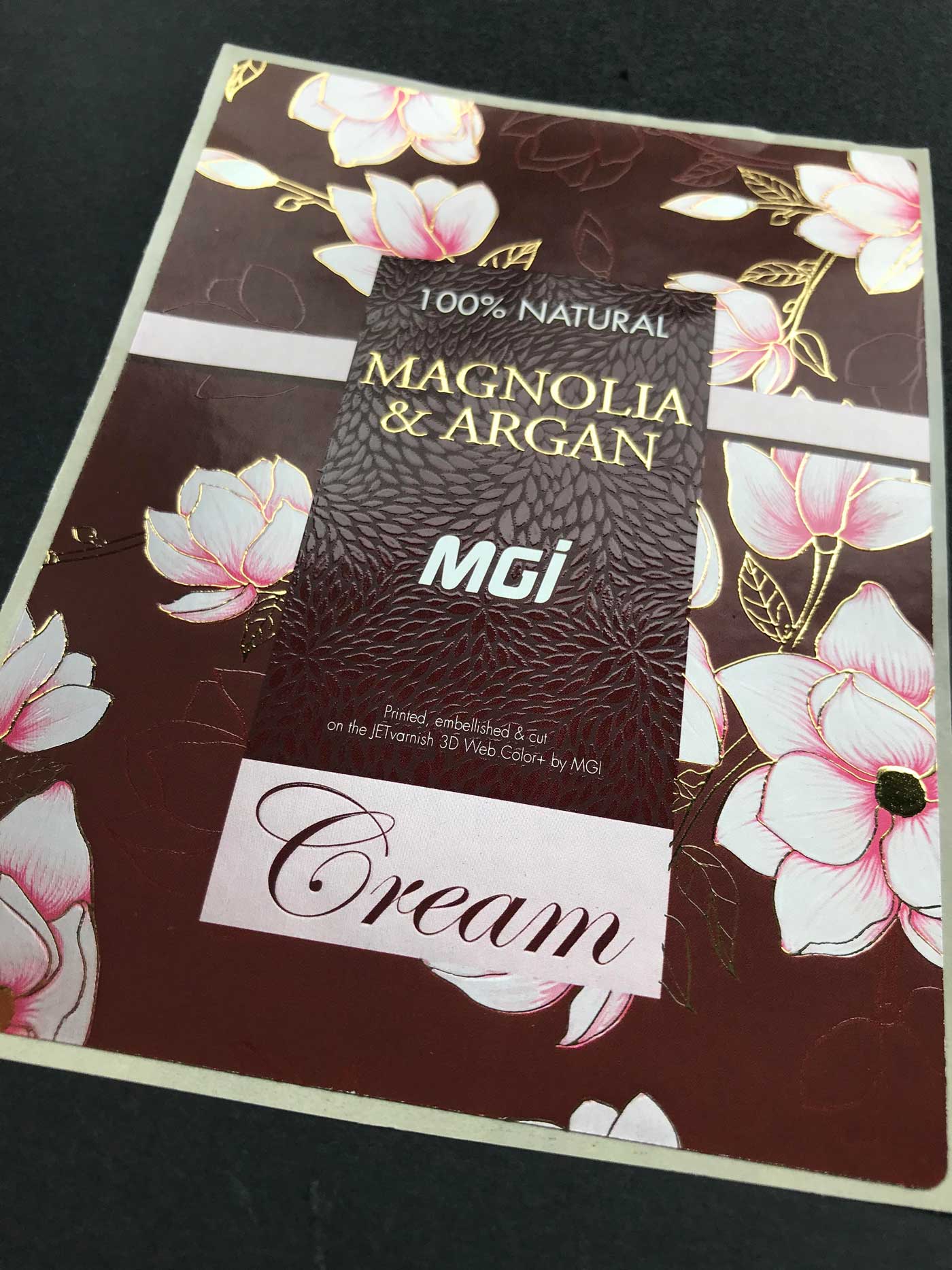

100% digital finishing, selective varnish, hot foil stamping & variable data

in a single pass from MGI Digital Technology.

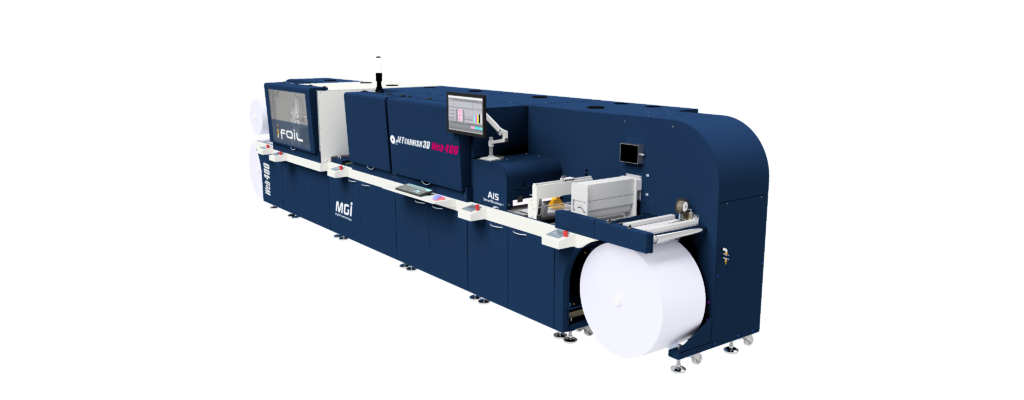

The JETvarnish 3D Web 400 is the latest generation of reel-to-reel digital finishing presses from MGI Digital Technology.

It enables single-pass UV selective varnishing and hot foil stamping, using a 100% digital process, on open or closed substrates, and for offset, flexo, toner or inkjet printing.

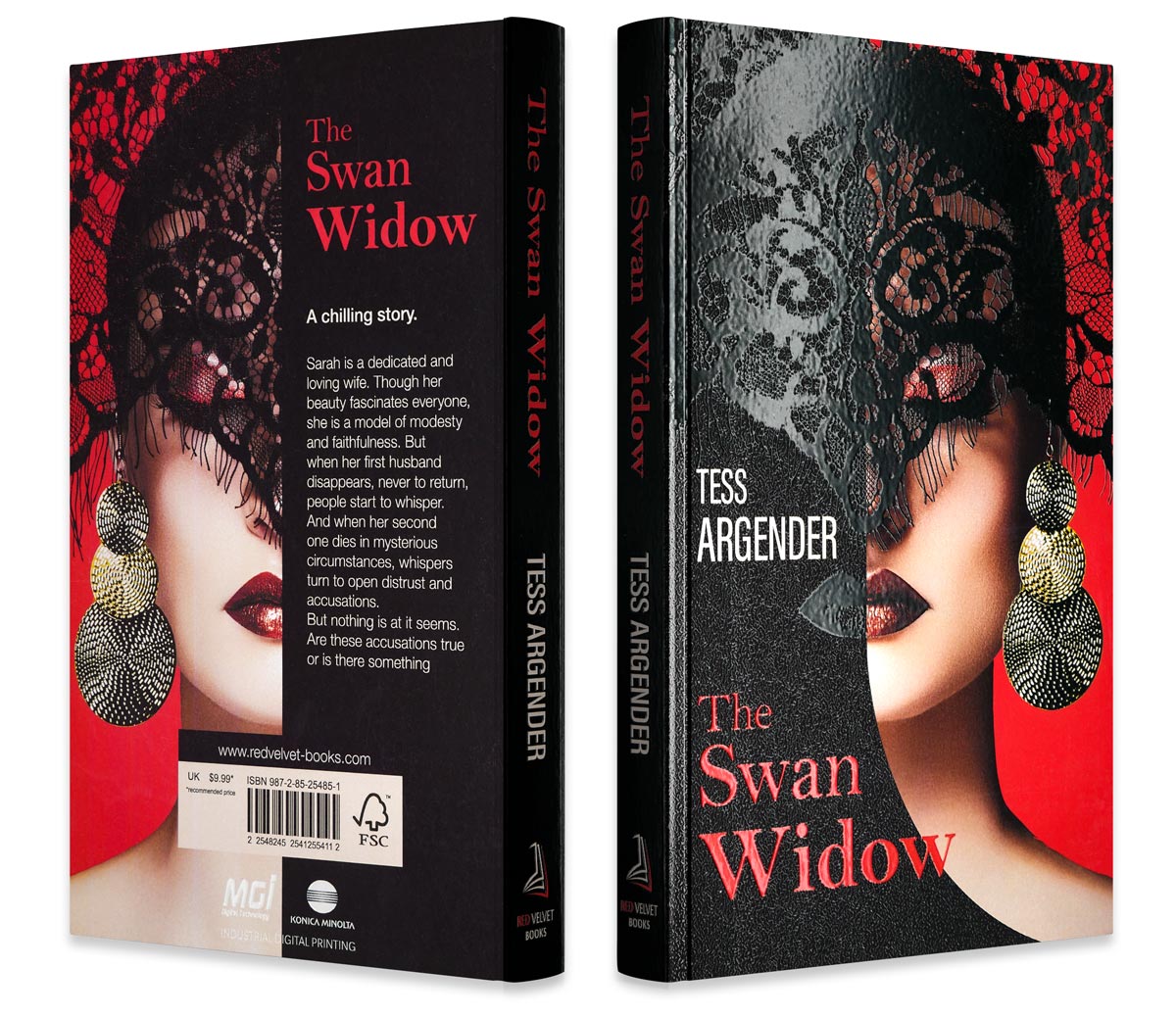

Dedicated to the self-adhesive label and flexible cardboard markets, the JETvarnish 3D Web 400 is the best response to brands' need for ever greater reactivity, quality and high added value. It enables converters and printers to reduce their customers' Time to Market, while transforming the impact of their labels and packaging on the shelf, in full compliance with their environmental strategies.

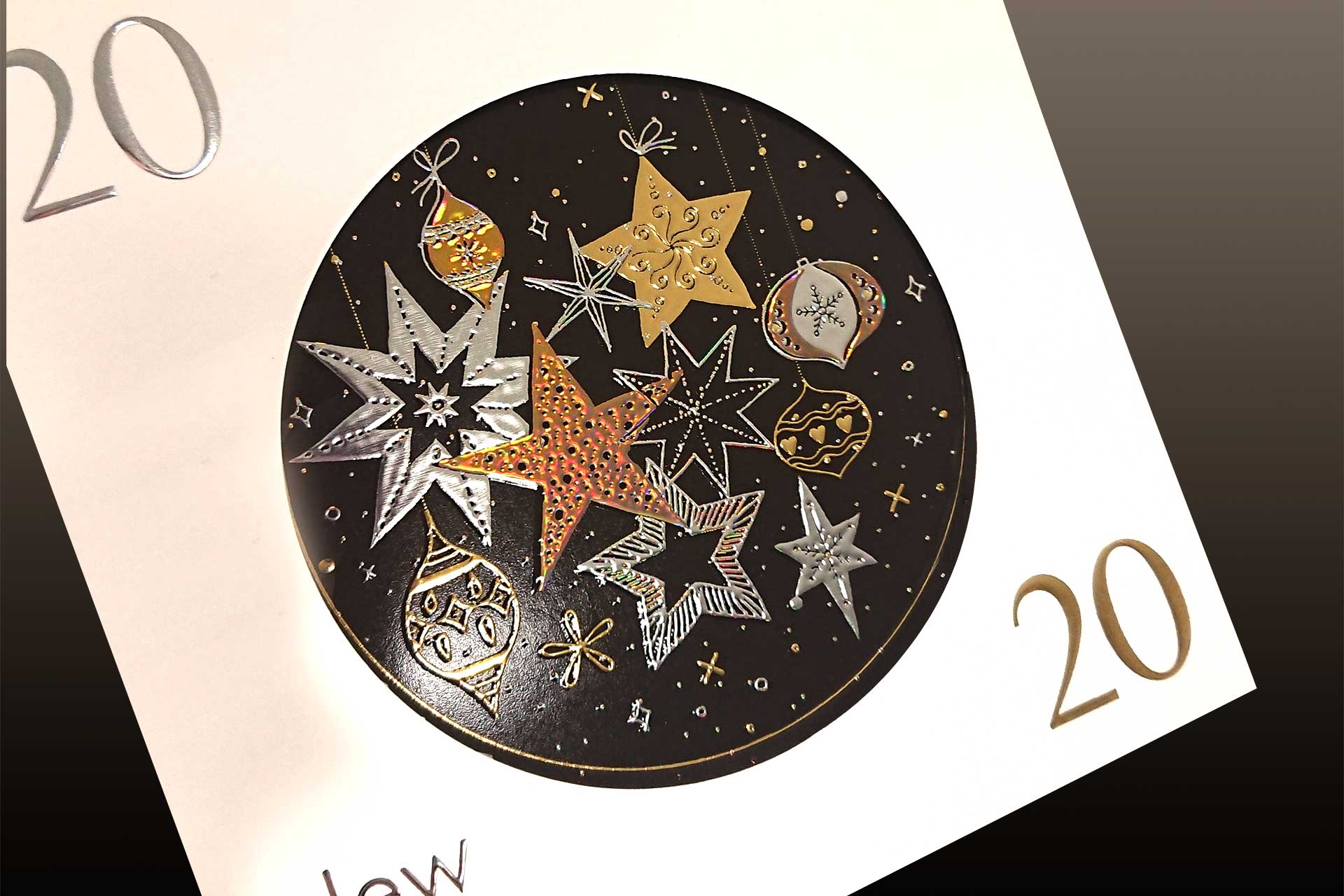

The versatile JETvarnish 3D Web 400 meets the most varied requirements for short, medium and long runs, enhancing basic four-color production with digital varnish and hot foil stamping in fixed or variable data, flat or embossed, facilitating multi-shot and versioning.

High Quality 100% digital

The JETvarnish 3D Web 400 enables inkjet application of UV varnishes, from 7 to 224 microns, for the most beautiful flat or relief renderings, with an unrivalled level of quality and stability, on all types of substrate, open, closed and synthetic. Its on-the-fly registration, controlled by the artificial intelligence of its AIS Scanner, offers perfect, stable registration throughout the print run, whatever the skew, stretch or contraction of the printed web. Hot foil stamping is applied to an inkjet-printed adhesive varnish, using the same methods as for UV varnish, guaranteeing a high level of quality.

Productivity, responsiveness and speed of implementation

Equipped with one or two MGI inkjet engines, the JETvarnish 3D Web 400 applies UV varnish and hot foil stamping in a single pass, at up to 50m / minute. Its on-the-fly makeready system makes it easy to run back-to-back prints one after the other. Its automatic cleaning system takes just 10 minutes a day, so you can concentrate on production.

Scalable 100% solution

Totally upgradeable, the JETvarnish 3D Web 400 is made up of modules that enable printers and converters to easily upgrade it as their finishing business grows. The JETvarnish 3D Web 400 is available in 4 configurations - with one or two inkjet engines and with or without hot foil unit - to suit all needs and budgets.

Ease of use, predictive maintenance, cost calculation and BàT in augmented reality

Controlled by a simple, intuitive interface that can be replicated on a digital tablet, the JETvarnish 3D Web 400 enables any operator to perform complex finishing operations that are impossible to achieve with conventional technologies. Its MGI Connect software suite integrates cost calculation, MGI Dashboard predictive maintenance, and MGI Approve augmented reality remote BàT for prime contractors. Hosted in a secure Cloud, MGI Connect can be deployed immediately, both within the print shop and with its customers.

No screens, no plates

100% digital, the JETvarnish 3D Web 400 applies UV selective varnish and hot foil stamping without the need for single-use plates, screens, plates and consumables, thanks to its inkjet technology.

Low-migration, desencrability and respect for the environment

The digital 100% process of the JETvarnish 3D Web 400 eliminates conventional intermediate consumables (plates, plates and screens) and solvents, which are particularly polluting and generate subcontracting, transport and packaging waste.

Its small footprint and low power consumption immediately reduce CO2 emissions. Its automatic on-the-fly setting eliminates waste, optimizing raw material consumption. Available in a low-migration(*) version, according to the SQTS standard for indirect food contact, and de-inkable on certain substrates according to Ingede 11, the only reference standard on the market, the JETvarnish 3D Web 400's UV varnish AND MGI hot foil stamping combine finishing with respect for the environment.