Mask by Mask, Together

March 30, 2020

Throughout Charlotte, 3D printers are whirring around the clock. Eight of them belong to your Charlotte Mecklenburg Library.

In the midst of the COVID-19 crisis, the phrase “we’re all in this together” has never been more apparent. A shortage of personal protective equipment for health care workers has brought together a local and national community of “makers” to fill the gap between supply and demand with creativity and collaboration.

On Monday, a surgeon from Atrium Health sent an email to Seth Ervin, the Library’s Innovation Leader, asking about the Library’s 3D printer capacity. Using a design from a local doctor, she was seeking community help in printing materials to assemble face shields urgently needed in area hospitals.

With libraries closed and the city sheltering in place, 3D printers were quickly moved from Library makerspaces to staff members’ homes, and round-the-clock production began immediately.

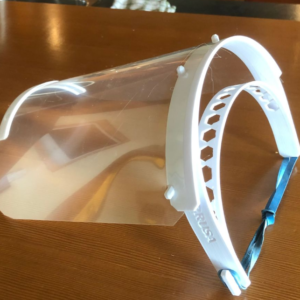

Aubrey Hedrick, the Library’s Makerspace Coordinator, oversees the Library’s involvement. Each mask requires a faceplate mechanism, printed on the 3D printers. The parts are collected in batches and brought to a centralized area where they are sanitized and assembled with a face shield cut of clear plastic. Library printers can produce parts for about 20 masks each day. “We are contributing to a much larger community effort, with participants ranging from local makers to professional designers, led by a team from UNC Charlotte, Charlotte Latin, and Discovery Place Education. They’ve formed a group called Charlotte MEDI (Medical Emergency Device Innovation) and have reached out into the maker community to build a solid process and infrastructure to make it all happen. The Library is glad to help.”

Aubrey Hedrick, the Library’s Makerspace Coordinator, oversees the Library’s involvement. Each mask requires a faceplate mechanism, printed on the 3D printers. The parts are collected in batches and brought to a centralized area where they are sanitized and assembled with a face shield cut of clear plastic. Library printers can produce parts for about 20 masks each day. “We are contributing to a much larger community effort, with participants ranging from local makers to professional designers, led by a team from UNC Charlotte, Charlotte Latin, and Discovery Place Education. They’ve formed a group called Charlotte MEDI (Medical Emergency Device Innovation) and have reached out into the maker community to build a solid process and infrastructure to make it all happen. The Library is glad to help.”

The Library team began using Library supplies, but those are quickly running out. Charlotte MEDI has set up a gofundme campaign, and donations will be used for purchasing 3D filament, PETG sheeting (for the face shield) and elastic, which is already becoming hard to find. The group is also working on scaling up production by involving area manufacturing companies with injection molding capabilities. Today, the group’s goal is to produce 1,000 masks per week. With injection molding, that can increase tenfold.

Printers are whirring. We’re in this together.

Library makerspaces began in 2015 with an investment in innovation from the Knight Foundation. The latest is at the newly renovated North County Regional location, outfitted with a generous gift from Lowe’s Corporation.