When to use a Hot Melt Roofing System

Here’s an introduction to hot melt roofing and some suggestions as to when you should consider hot melt for your flat roofing project.

What is Hot Melt?

Hot melt is a membrane that is applied as a hot liquid directly to a prepared structural deck to create a completely seamless, monolithic layer. It is suitable for use as the waterproofing layer in most new build flat roofing applications, when covered by suitable protection.

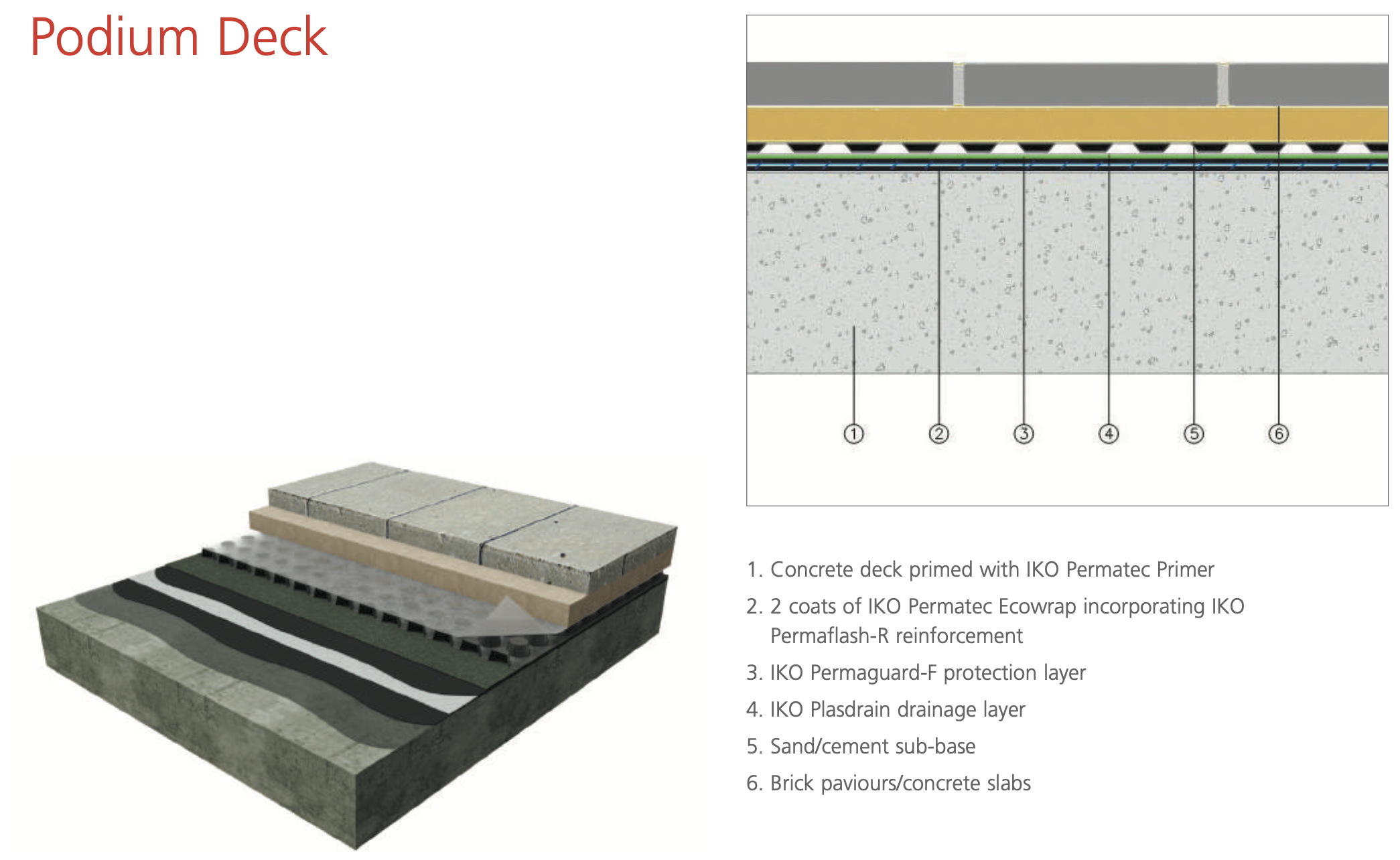

The most common application of hot melt is as an inverted roof system, where the membrane is laid directly on the deck and insulation is laid on top, weighed down with ballast materials such as 20-40mm gravel or 50mm paving slabs. Hot melt can also be used for green roofs, podium decks and substructure waterproofing.

SIG Design & Technology supply IKO Permatec Hot Melt, which was the first hot melt system to be manufactured in the UK.

Benefits of Hot Melt Roofing

- Long-term Performance – formulated to last the lifetime of the building on which it is installed.

- Monolithic – forms a completely seamless waterproof barrier. No seams or lap joints, no risk of water tracking, no legacy costs of poor workmanship or detailing.

- Ultra-Durable – unaffected by standing water, dilute acids or fertilisers.

- Cost Effective – can be installed to zero falls, and at temperatures down to -18°C, without replacement during the lifetime of the building.

When to Consider a Hot Melt Inverted Roof

When is hot melt roofing the best flat roofing system choice? SIG Design and Technology design and supply the best solution for our customers’ waterproofing needs, which means choosing the most practical, cost effective system for their project.

Here are some examples of when our clients choose hot melt.

1. Waterproofing a Concrete Deck

When you have to waterproof a concrete deck, hot melt is the simplest, swiftest solution, with no need to drill into the deck for fixing, fast curing times and no need for a separate vapour membrane. It is commonly used in projects from small residential terraces right up to the large inverted roofs of commercial offices and modern shopping centres. Hot melt is also ideal for waterproofing a podium deck, including on shopping centres, car parks and railway stations.

2. Designing a Green Roof

We frequently recommend Hot Melt for a green roof design. Used with the right substrate, it has several benefits over single ply membranes, including its long lifespan and monolithic character. For green roofs, IKO’s Permatec Anti-Root (the world’s first monolithic root resistant hot melt waterproofing system) is recommended.

The green roof build up should be calculated to be at least the equivalent of the minimum ballast weight of an Inverted Roof System. As part of our design service we would carry out a Ballast Wind Calculation for you to confirm this.

3. Designing a completely Flat Roof

It is best practice is for all flat roofs to have a fall to ensure good drainage. However, designers often decide to for a variety of different reasons to have completely flat roofs, for example, when there is no space for falls to be incorporated into your roof design.

Most waterproofing systems require at least minimal falls to comply with codes of practice and BBA certification, but with hot melt the roof deck can be completely flat if certain other requirements are met. This can be particularly useful when planning considerations restrict building heights.

IKO Permatec Hot Melt is suitable for use in zero falls conditions. It may be a requirement of your system warranty that there should be no back falls (which could create areas of ponding), and we would always recommend compliance with the recommendations of BS6229:2018.

4. Fast Track Flat Roofing

On a tight programme, a fast curing hot melt inverted roof system saves installation time without any loss of quality. This makes it particularly popular on fast track commercial or public new builds and housing. As hot melt can be installed at temperatures as low as -18 Celsius, winter installation is also not an issue.

5. Cost Savings on Insulation, Falls and Maintenance of Flat Roofs

When you need to save on the cost of tapered insulation or screed to falls, hot melt provides an opportunity to remove the need for tapers and screeds altogether, making the solution more competitive.

IKO Permatec hot melt is formulated to last the lifetime of the building on which it is installed, so with simple maintenance, you don’t need to allow for replacement costs. It is even possible to upgrade the insulation at a later date without disturbing the weatherproofing.

6. Complex Roof Layout and Penetrations

If your new flat roof has a complex layout where falls are difficult, or if you need to install HVAC equipment, or the roof has several penetrations, hot melt can simplify the installation.

As well as removing the need to design in falls, an IKO Permatec hot melt roof can be simply detailed to allow for a wide variety of upstands, penetrations and structural connections.

For example, installing roof top plant can be problematic due to the risk of cold bridging. With a hot melt inverted roof, a floating concrete plinth can be installed on top of the insulation, removing any chance of cold bridging by placing the plant completely outside the membrane and insulation system.

6. Designing a Flat Roof for a Long Life

The membrane in an inverted roof is covered and therefore protected from the elements, footfall and mechanical damage throughout its life. With hot melt, the membrane is also fully adhered to the deck, so that if it does become damaged, water cannot migrate between membrane and roof structure and repairs are relatively straightforward. If a leak does arise, it is much easier and cost effective to find and repair with a hot melt system than with membrane systems.

7. Designing a Flat Roof with Environmental Considerations

We recommend IKO Permatec Hot Melt which has a number of environmental benefits:

- It is manufactured in the UK, reducing carbon miles.

- It is made with 45% recycled content;

- It has been developed with zero wrapper waste, so that there is virtually no packaging for disposal;

- Its long life gives it a very respectable whole lifecycle cost – talk to us for details.

Things to Consider when specifying a Hot Melt Roofing System

Some points to note:

- Installing hot melt roofing should be carried out by an experienced, certified contractor. Have your inverted roof installed by an IKO Permatec trained and qualified roofing contractor.

- The structural deck should be capable of supporting the weight loading of an inverted roof system, which would usually be between 95kg/m2 and 140kg/m2.

- The roof should be designed to incorporate adequate drainage and overflow, should consider thermal requirements and wind conditions and should comply with the recommendations of BS6229:2018.

- The waterproofing system must be fully tested (usually electronically or by flood test) for damage prior to the installation of the insulation and loading coat (ballast/pavers/green roof).

SIG Design & Technology in conjunction with IKO Plc can design your hot melt inverted roof for you as part of our supply service for IKO Permatec hot melt. Get in touch with us for details of our free service.

More Information

- Visit our Permatec Hot Melt Pages for more information about the product

- Check out a few example projects using Permatec Hot Melt Roofing system in their roofing:

- 5 Broadgate by Make Architects for British Land / Blackstone JV

- Tasman House, Fitzrovia by Buckley Gray Yeoman

- Seven Secondary Schools in Hertfordshire by Rock Townsend and Kajima Consortium

- The Evelyn Grace Academy by Zaha Hadid

- Ravensbourne College by Foreign Office Architects

- St Johns Therapy Centre by Henley Halebrown Rorrison

- Westfield Stratford City by Fletcher Priest Architects

- Visit our Case Study Pages

- Contact us for advice on your project or post a comment below with your questions.

I was very happy with the work they did. I totally welcome them again and I totally honor them all especially for giving them so many ideas.