Researching vendors for your project can be exhausting. Countless hours can be spent on the phone with extruders, fabricators, anodizers and powder coaters, and more–requesting quotes, sending prints, reviewing options. Contract manufacturers are attractive because they save you time and money. They leverage their networks of vendors and suppliers to make sure you get the best deal.

By definition, your contract manufacturing partner (CM) should be your most directly accessible and accountable supplier. There is no hard and fast rule that helps to always determine the best CM for your project. There are many aspects to consider when selecting your CM, and prioritizing those aspects intelligently is part of what makes a successful purchase.

In order to pick a CM that best fits your project, you need to name your priorities and analyze your current strategy, and recognize there is no one-size-fits-all strategy.

Name Your Priorities and Analyze Your Current Strategy

Can you put your finger on what the most important part of your relationship with your contract manufacturer is? Maybe not, because there are so many aspects that all seem critical. You need your parts on time. They need to be of a certain quality. Your CM’s expertise and responsiveness are key too. You’ve likely narrowed down a general area that you’d like your CM to be located within to simplify logistics, so their location is important. It can be tough, but prioritizing your values is important so that you’ll be able to best select a CM and then determine the success of your CM relationship.

Consider Cost and Markup

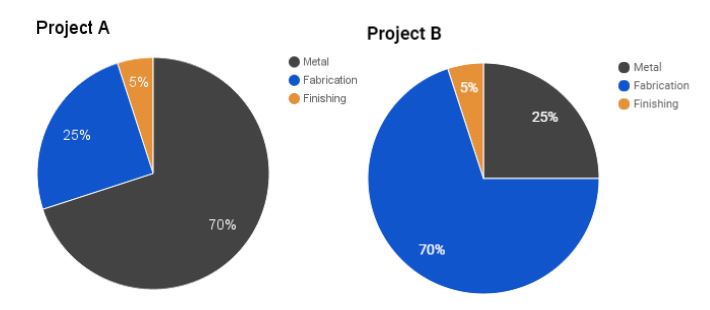

Think of the services you need and their relative costs as a pie graph.

In the examples below, the largest portion of the cost of Project A is the metal. These parts require minimal fabrication for each part–maybe just a few holes punched, for example. The fabricator’s markup will be relatively small compared to the extruder’s, as they are supplying the extrusions.

The opposite is true of Project B. Project B requires more machining, so fabrication costs are higher. The extruder would mark up this higher fabrication cost, so it would be most cost-effective to utilize any contract manufacturing services the fabricator offers to minimize your markup.

VERY LITTLE MACHINING NEEDED – THE EXTRUDER AS YOUR CONTRACT MANUFACTURER

As a general rule, the extruder should be your CM if your parts need little to no machining. With minimal fabrication, the fabricator’s markup will be smaller than the extruders. So when the extruder rolls the fabricator’s markup in, it will likely be less than if the fabricator had rolled up the extruder’s markup.

A LOT OF MACHINING NEEDED – THE FABRICATOR AS YOUR CONTRACT MANUFACTURER

Similarly, if your machining costs would make up the majority of your pie graph of relative costs, your fabricator should serve as your CM. That would mean your metal fab services get marked up once by the fabricator. On the other hand, if your extruder is your CM and your parts require more machining, your extruder may markup your fabricator’s services–meaning these services essentially get marked up twice. Consequently, if your parts require significantly more machining, it is worth considering taking your fabricator up on their contract manufacturing services to minimize markup.

The Myth of the One-Size-Fits-All Strategy

It might be easy to fall into the trap of thinking that the least expensive quote or the most well-known company is inherently the best contract manufacturing partner, but the truth is that there is no one-size-fits-all CM. The CM that best fits your project could go unnoticed by you because of these expectations. Make sure you’re evaluating each potential CM partnership by your priorities, and not by an unfounded idea that the biggest, cheapest, or closest company is always best for your project.

A contract manufacturing partnership has the potential to be a mutually beneficial relationship if selected thoughtfully. You know the priorities and costs of your project best, so choose the right metal fabrication expert to manage the details.