8 Common Problems Found In Ship’s 2-Stroke Marine Engines

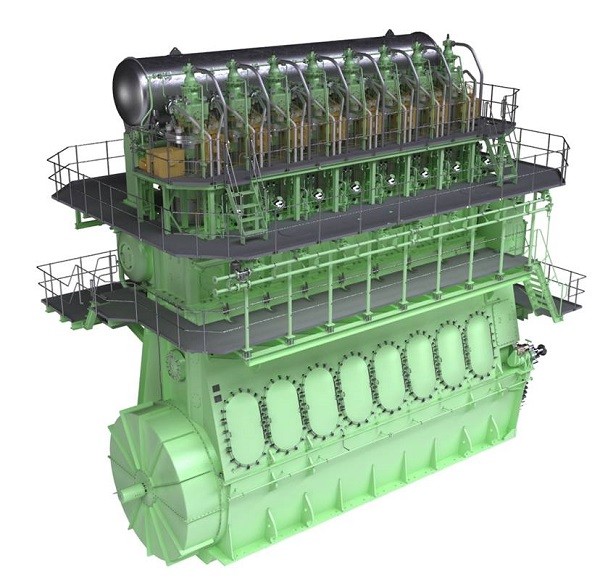

The 2-stroke marine engine is the main propulsion power source and also the biggest machinery on a ship. A great amount of efforts, resources and time is spent to ensure that this massive engine runs smoothly and efficiently, taking the ship from one port to another without breakdowns.

But no matter how many precautions are taken, problems/breakdown are bound to take place considering the complexity and number of parts the 2-stroke marine engine has.

In this article, learn about eight most common problems that are found in the ship’s 2 stroke marine engine and what should be done to tackle them.

1. Stuck Fuel Rack: This is one of the most common problem with oil fired 2 stroke marine engines. The governor controls the fuel pump delivery through a fuel rack, which is a combination of mechanical links. Sometimes the fuel rack gets stuck leading to lack of fuel supply in the concerned unit which results in either fluctuation in the engine RPM if running or engine will not start from standstill.

Solution: All the mechanical links of the fuel rack must be well lubricated and greased before starting the main engine. If after starting the main engine, the engine rpm is constantly fluctuating even at lower speed in calm weather, check all the fuel rack as one or more of them must be stuck.

2. Starting Air Valve Leakage: Any leakage from the starting air valve will lead to hot gasses going back to the engine air line, which may contain thin oil film. Such mixture of oil and film can lead to starting air line explosion. This kind of explosion is not very common now-a-days due to safety features incorporated in the air line (bursting disk in MAN and relief valves in SULZER/ Wartsila engines). However, one cannot overlook the possibility of malfunctioning of such devices which can lead to explosion.

Solution: Normally, there is no remote monitoring of temperature for the air line supplying air to starting air valve. The best way to determine such fault is to check the temperature of the air line manually during maneuvering. This problem is more likely to occur when the engine is started frequently and not when engine is running continuously.

Read: Operation of Main Engine Air Starting System

3. Fuel Leakage/ Fuel Valve Malfunction: Problem in the fuel system are also commonly observed in the main engine. When there is a deviation in temperature of one unit, the fuel system, especially the fuel valve needs to be checked. Overhauling and pressure testing of fuel valve must be done as per PMS. If the engine is maneuvered in diesel oil, there are chances of leakage from the pump seals. Also if the fuel treatment is improper and the fuel temperature is not maintained, it can lead to cracks and leakages in high pressure fuel pipe.

Solution: Any leakage in the main engine fuel oil system can be determined from the “high pressure leak off tank” level and alarm.

4. Sparks in the Main Engine Exhaust At Funnel: Marine engineers normally experience getting a call from bridge officer informing about sparks coming out from the funnel, which is the main engine exhaust. Sparks from funnel occur due to slow steaming and frequent maneuverings, which build unburnt soot deposits on the EGB boiler path.

Solution: Frequent cleaning (monthly) of the exhaust gas boiler to be preferred by the ship staff to avoid this problem.

5. Starting Air Leakage: This is also one of the most underrated yet common problems related to marine engines. The control air supplies air to different parts and systems of the main engine. It is always in open condition when the engine is in use. Small leakages are normal and can be rectified only by tightening or replacing the pipes or joints.

Solution: When the Engine room machinery is in working condition it is difficult to hear any air leakage sound. The best way is to trace all the air lines and feeling all the connections/ joints by hand for air leakage. The easiest way to find air leakages is when there is an intentional black out done for any job. At this moment all the machinery will be in “stop” position and leakage sound (a hissing noise) will be loud and clear. Note the leakage area to perform the repairs later.

6. Stuck Air Distributor: Air distributor is responsible for maintaining the air supply which opens the starting air valve in the engine cylinders. Since it’s a mechanical part, it is prone to malfunctioning, especially getting stuck. The main engine will not start if air distributor does not supply air to open the starting air valves as no air will be present in the cylinder to commence fuel combustion

Solution: Many engines such as MAN B&W have their air distributor located at the end, with inspection cover, which can be opened when the engine is not running for inspection and lubrication to avoid this problem.

Read: 10 Important Checks to Make Before Starting Main Engine

7. Malfunctioning of Installed Gauges: It is very important to have local parameter gauges on various systems of the main engine. To note down the readings in the log book, it is always recommended to take the the local readings rather than remote readings. Often engineers find that one or two gauges (pyrometer, pressure gauges, manometers etc.) installed in the main engine are not working or in dilapidated condition. The reason for such condition can be due to loose parts and connections, and even vibrations.

Solution: Replace the faulty parameter gauges with new ones as early as possible.

8. Faulty Alarms and Sensors: The main engine is fitted with various sensors, which measure and transmit actual data to alarm console. Due to factors such as vibration, high temperature, humidity, dust etc. these sensors can malfunction leading to false alarms.

Solution: A routine checks needs to be performed on all engine room sensors and alarms. Different main engine safety alarms and trips also to be tried out at regular basis and faults to be attended immediately.

Do you know any other common 2-stroke marine engine problems which should be added to this list? Let’s us know in the comments below.

Checkout our Premium eBook:

Maintenance of ship’s main engine includes inspection and calibration of its important parts. A Guide to 2-Stroke Engine Components is an ebook which offers information on construction and design of important marine engine components of 2-stroke engines.The guide also includes step-by-step procedures for inspection and calibration of engine parts which are required during maintenance work. Click here to know more

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Hi

The issues mentioned here are basic issues, not special problem. They are usually experienced when manufacturer’s guidance is not followed as described in the maintenance manual.

Hi everyone, I have a problem on my engine wartsila vasa 22, I misured a high quantity to SO2 on exsaust gas. I note after 400 hours of work over 17% of fuel oil in engine oil . I cecked the cilinder pressure it is ok , the leakage is correct , and the injiection valve is ok . Someone had experience about this problem? what is the reason or the issue ? Can someone help me?thanks

i couldnt order any of these books as it is showing authorisation failed hw can i order this book is there any possiblities

I have problems with engine man d4828 le 403 V8 800 horse power .

It gave me alarme for coolant press exp. Tank then it gave me remote slow down and the both engine didn’t take high RPM it reach 1000 rpm only .

You can post all your queries in our forums for speedy and multiple replies: https://forums.marineinsight.com

Good day everyone

This engine problems is very nice know for every ship’s engineer. Now that problems is usually is standard problems and use for every ship’s engineer.

Good Day

Working on MAN B&W 6S50MC Engine.

Recently observed Main Engine RPM dropping momentarily from 101 to 83 and regain after 30 secs to 101.

Kindly assist

May I know the root cause why main engine rpm cannot increase at bridge control, its only 100, the rated rpm is 215. Main engine is AKASAKA 3400kw. .At Engine side manual control no problem to increased at desired rpm.

How will u remove tie rods if they are broken in between…. Specially the bottom half

Mukul

Your answer is elaborately described in Prof D. K. Sanyal. Marine Diesel , new edition and also study Lamb question answer.

Now a days vessel specially oil tankers in any part of the world off course except Fujairah, we all having a big problem with the HFO as far as the ME and Diesel Generators are concerned.

In some ports they will blindly message to us that the sample is lost and till the time we arrive at the NCP. In spite of having fuel analysis kit provided we surely make out the water content but what about the other impurities.

Last vessel were bunkering from Nigeria Off Port Limit, and I specifically mentioned the bunker personnel that I would send my 4th engineer to see the samples physically.

As usual without getting any analysis report after 20 days we had to use that bunker. It was long passage of 42 days. 20 days after using the oil we had no problems. But after that my latest purifier of Alfa Laval started giving problems and the sludge was just hard electric putty and ke6on and on . Every day job was to clean the bowlhood of the running purifier and keep it standby for the UMS time.

As the days go on the changing intervals of purifier increased to 5 hrs and ultimately leading to change of the 25 microns filters auto back wash in every 2 hrs. What I observed, the sludge was somewhat of wax of paraffin. Reporting to the office was nothing. Now we have to make another 12 days voyage keeping the fingers crossed, nothing should happen to the latest MAN B&W ME G C-8 Tier II.

My query is that why we have to suffer by knowing the fact that this fuel will let us awake may be for next 22 days, we’re taking this bunker, where you r sure that only one yr old vessel can have a expens, which might require changing of all fuel pumps all parts and that too to maintain chartered speed of 14 k knots.

If we don’t have a better quality of HFO in the world why not change the entire scenario to MDO or LSMGO, where you have the options.

May in the near future we will have to take SLUDGE mixed with some chemicals as our bunker as FOT is not much effective.

This is the problems facing we on board, going through sleepless nights for how long I don’t know.

situation were 2 cylinders are not firing among 5 cylinder heads. but the fuel rack is distributing, what should be the issue.Hyundai MAN B&W 6550 MC_C