Insulating Matting – IEC 61111 Specifications & Selection For Switchboard Matting

Published 11 Jan 2018

Uploaded By: Chris Dodds - reading time 5 minutes

Insulating matting is a essential component of electrical safety and is specified and installed to provide protection against electrical shock and hazards around electrical equipment, such as switchboards and switchgear – this can include Low Voltage, Medium Voltage & High Voltage.

As part of a facilities standard risk assessment, where a potential for electrocution is present, then electrical insulating safety matting (commonly referred to as switchboard or switchgear matting) is recommended in the HSE’s Safe Working Practices for Electricity At Work document (HSG85) where it references BS EN 61111: 2009 (Live Working: Electrical Insulating Matting British Standards Institution).

“providing and using correct personal protective equipment (PPE) to reduce the

risk of contact with live parts or earth, eg insulating gloves, insulating matting

(see BS EN 61111:200917). If there is a risk of burns from arcing or flashover

that cannot be avoided, consider the use of adequately rated, thermally

insulating, flame-resistant, arc flash clothing or PPE (including face/eye protection).” HSG85

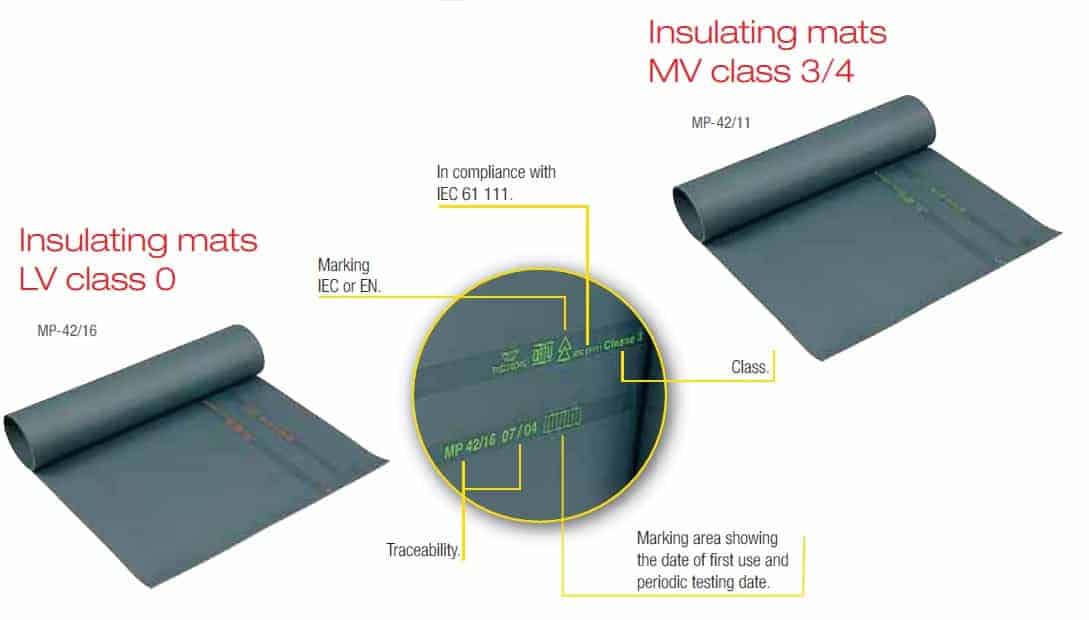

The range of CATU insulating matting conforms to the standards set out in IEC 61111 and provides MV-HV electrical protection for personnel

The IEC 61111 standard sets out the requirements that must be met and supersedes the standard CLC/TS 61111:2006 and includes the following significant technical points:

- General review of the requirements and test provisions

- Modification of the test procedure for slip resistance matting

- Specification of standard and alternative types of electrodes for the proof test

- The conditioning time for low temperature folding test of insulating matting

IEC 61111:2009 is applicable to electrical insulating matting made of elastomer for use as a floor covering for the electrical protection of workers on electrical installations, including 11kV and 33kV substations.

LV MV HV Insulting Matting Explained

Selection of insulating mats for specific applications depends on the worker exposure to operating voltage and matting is tested to withstand certain specified voltages – referred to as the safe working voltage detailed below. Electrical safety matting is tested to a higher voltage than the certified use voltage – the voltage at which the matting is certified to is the Safe Working Voltage.

CATU Electrical insulating matting is specified and tested to IEC 61111 Category C with working temperatures to – 40°C for the following voltages:

- LV Insulating Matting – Class 0 Safe Working Voltages 600V 1000V

- MV HV Insulating Matting – Class 3 Safe Working Voltage 3.3kV 6.6kV 11kV 15kV 26.5kV

- MV HV Insulating Matting – Class 4 Safe Working Voltage 3.3kV 6.6kV 11kV 15kV 33/36kV

Products that are covered by the IEC 61111 standard include live working, electrical insulating materials, insulating matting, elastomers, floor coverings, electrical safety, electric shocks, safety devices, occupational safety, classification systems, grades (quality), marking and testing.

See live working tools for further information about insulated tools in accordance with IEC Standards for working on energised low voltage cables.

Protecting Jointers & Electrical Engineers When Working Live On Cables & Switchgear – comprehensive ranges of insulating matting and insulated tools.

Catu Electrical insulating matting

Electrical insulating matting is available in roll form for placement and rolling-out in front of medium/high voltage switchgear rooms, motor control centres (MCC), traction power substations and UPS rooms.

Portable pre-cut insulating mats are available to provide protection to site engineers and cable jointers working on electrical installations in plant and lift control gear rooms – often used to provide electrical protection when 11kV/33kV jointing, terminating and glanding cables into electrical distribution equipment.

➡ Class 0 Matting | Class 1 Matting | Class 2 Matting | Class 3 Matting | Class 4 Matting

| CATU Electrical Product Reference | Insulating Class | Min Voltage | Max Voltage | Matting Thickness | Mat Dimensions | Weight |

| CATU MP-11/11 | 0 | ≤1000 V | ≤1500 V | 2 mm | 1 x 1 m | 2.9 Kg |

| CATU MP-11/16 | 0 | ≤1000 V | ≤1500 V | 2 mm | 0.6 x 1 m | 1.4 Kg |

| CATU MP-42/11 | 3 | ≤26500 V | ≤39750 V | 3 mm | 1 x 1 m | 4.5 Kg |

| CATU MP-42/16 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 1 m | 2.9 Kg |

| CATU MP-42/66 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 0.6 m | 1.8 Kg |

| CATU MP-60/05-1 | 4 | ≤36000 V | ≤54000 v | 5 mm | 0.6 x 1 m | 4.4 Kg |

| CATU MP-100/02-10 | 0 | ≤1000 V | ≤1500 V | 2 mm | 1 x 10 m | 29 Kg |

| CATU Electrical Product Reference | Insulating Class | Min Voltage | Max Voltage | Matting Thickness | Mat Dimensions | Weight |

| CATU MP-60/03-5 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 5 m | 14 Kg |

| CATU MP-60/03-10 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 10 m | 28 Kg |

| CATU MP-100/03-5 | 3 | ≤26500 V | ≤39750 V | 3 mm | 1 x 5 m | 25 Kg |

| CATU MP-100/03-10 | 3 | ≤26500 V | ≤39750 V | 3 mm | 1 x 10 m | 53.5 Kg |

| CATU MP-60-/05-5 | 4 | ≤36000 V | ≤54000 V | 5 mm | 0.6 x 5 m | 28 Kg |

| CATU MP-60/05-10 | 4 | ≤36000 V | ≤54000 V | 5 mm | 0.6 x 10 m | 44 Kg |

| CATU MP-100/05-5 | 4 | ≤36000 V | ≤54000 V | 5 mm | 1 x 5 m | 45 Kg |

| CATU MP-100/05-10 | 4 | ≤36000 V | ≤54000 V | 5 mm | 1 x 10 m | 89 Kg |

Complete range of LV-HV Insulating Matting for all medium and high voltage switchgear, switchboard and substation electrical safety protection up to 33kV.

Recommendations For Use & Storage of Matting

It is vital to store and use electrical insulating mats in the correct manner in order to prolong their lifespan and ensure they continue to function and provide the insulation levels required. When storing or transporting the matting it should be properly stored and should not be bent or deformed.

The insulated mats should also not be stored or used close to any excessive heat sources or exposed to direct sunlight for long periods. The ideal storage temperature for the mats is between 10°C and 21°C.

When using and installing any insulating matting, a visual inspection should be carried out first. If the mats are dirty they should be cleaned with soap and water and then dried, respecting the operation temperatures mentioned previously.

Ideal operating temperatures are between -40°C and 55°C and the mats should not come into contact with any chemical products as this can also damage the rubber. When installing the mats, place them on a clean smooth floor devoid of any aggressive elements.

Once installed, periodic inspection of the insulating matting should be carried out and mats should not be used if they have not been electrically tested for 12 months.

Typically, Class 1, 2, 3 and 4 matting should be tested every 12 months in accordance with IEC61111 – often a visual inspection for low voltage Class 0 insulating matting is adequate depending on matting condition. Aged matting showing clear deterioration should be subject to routine dielectric test to check and ensure insulating levels are maintained.

Insulating Matting FAQ’s

How Do Insulating Mats Work?

Rubber is a natural dielectric material and therefore inhibits the flow of electric charge as a result of its molecular structure preventing the free flow of electrons.

Where Should I Use Insulating Matting?

Insulating matting should be installed in front of low, medium and high voltage switchboards, in front of machine control gear, in plant and lift gear control rooms and as portable protection for site engineers working on live electrical equipment.

Matting should also be used in conjunction with electrical safety equipment such as insulating gloves, insulating boots and in some cases arc flash protection clothing.

What Sizes Are Mats Available In?

The working voltage and size of matting is dependent upon the class of the mat. CATU insulating matting is supplied in 5m or 10m long rolls and as either 0.6m wide, 1m wide or 1.2m wide dependent on class. The thickness of the matting is also dependent on voltage class.

What Is The Double Triangle?

Matting with the “double-triangle” symbol confirms the insulating matting is suitable for live working according to IEC 60417-5216.

♦ Further Reading

For more reading about Electrical Safety, read the T&D blog:

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

- Can Arc Flash Clothing Save Cable Jointers Lives?

- Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Further Reading

-

Insulating Matting (LV MV HV Switchgear Mats) Size: 288.21 KB