Traulson Refrigerator Retrofit

About the project

Retrofit older commercial refrigerator with digital controls and web interface

Project info

Difficulty: Moderate

Platforms: Raspberry Pi

Estimated time: 4 days

License: GNU General Public License, version 3 or later (GPL3+)

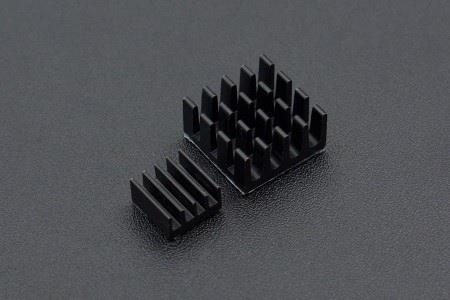

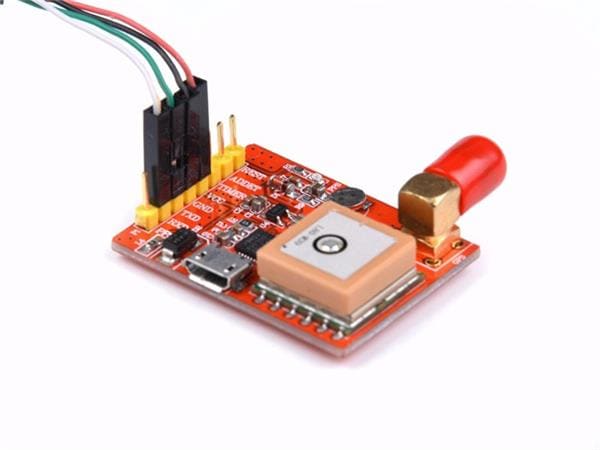

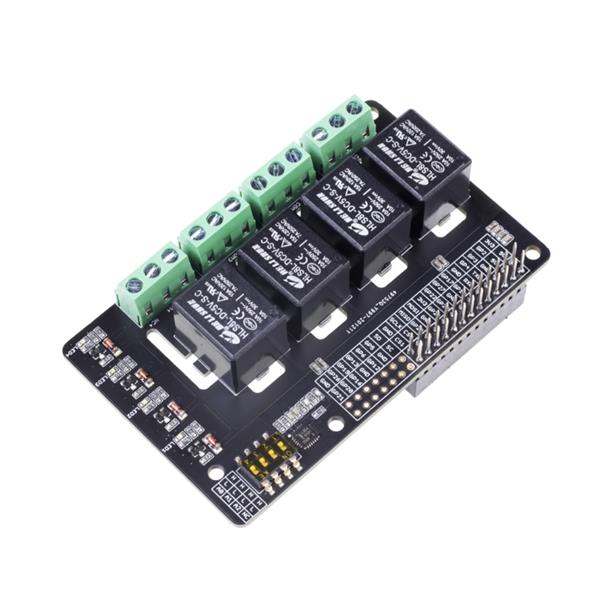

Items used in this project

Hardware components

Story

I have an old Traulson refrigerator/freezer that is very inefficient and costly to run. I've added digital monitoring and control using a Raspberry Pi and Node Red, as well as new LED lights . The goals were to:

1- Make the unit more efficient by removing the old analog controls.

2- Provide accurate monitoring to adjust for lowest amount of power used to achieve acceptable internal temperature .

3- Replace old dim and hot incandescent light bulbs with LED strips.

4- None of these modification could look non stock.

5- Replace 4 watt heater for the ice maker feed tube and replace with a controlled heater.

I started with the lighting last year, this had a dramatic improvement in the appearance of the unit as well as being able to see what you were looking for. I then added the temperature probes and monitoring using Cayanne/My Devices. This involved drilling holes through the freezer and refrigerator compartments and installing new temp probes. In about 1 week I was able to decrease the temp setting on the analog control from 9.5 to 4 and still maintain a temp of zero degrees F inside the freezer. Since I did not want to be at the mercy of an outside vendor for the control of my food safety, I used Node Red to write a control loop to monitor temps and turn on the freezer and fridge compressors when needed. Over all I am very pleased with the final product and all of the goals were achieved.

Leave your feedback...