The Then and Now of NPE

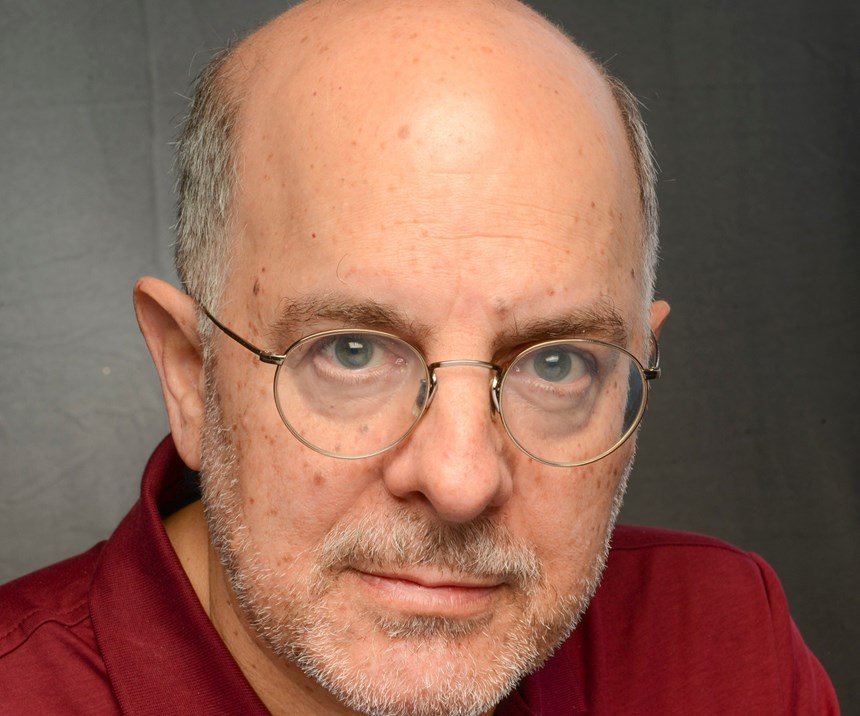

Matt Naitove, executive editor of Plastics Technology, shares the experiences and insights he’s gained from attending 15 NPEs since 1973.

NPE has been a plastics industry “must-attend” event for more than 70 years. Participants representing more than 20,000 companies from all over the world attend. But how has it grown and evolved over the years?

Matt Naitove, executive editor of Plastics Technology, has some pretty good insight. Naitove began attending the show in 1973 as a cub reporter and this is his 16th NPE. So, it’s fair to say he knows the ropes.

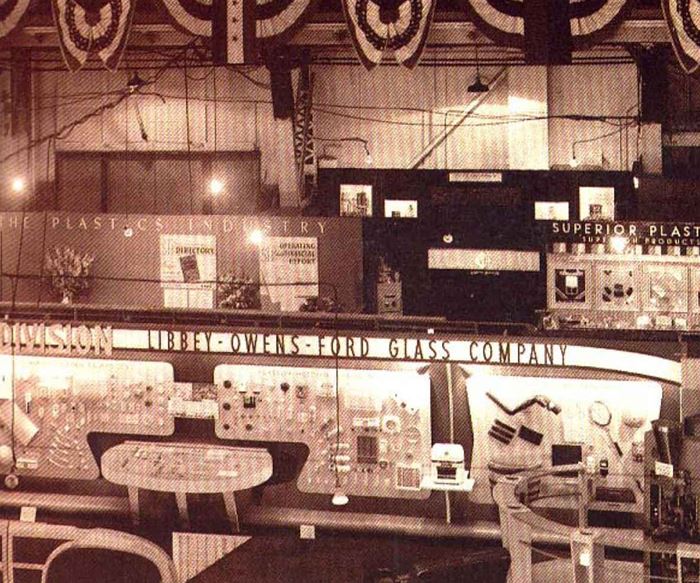

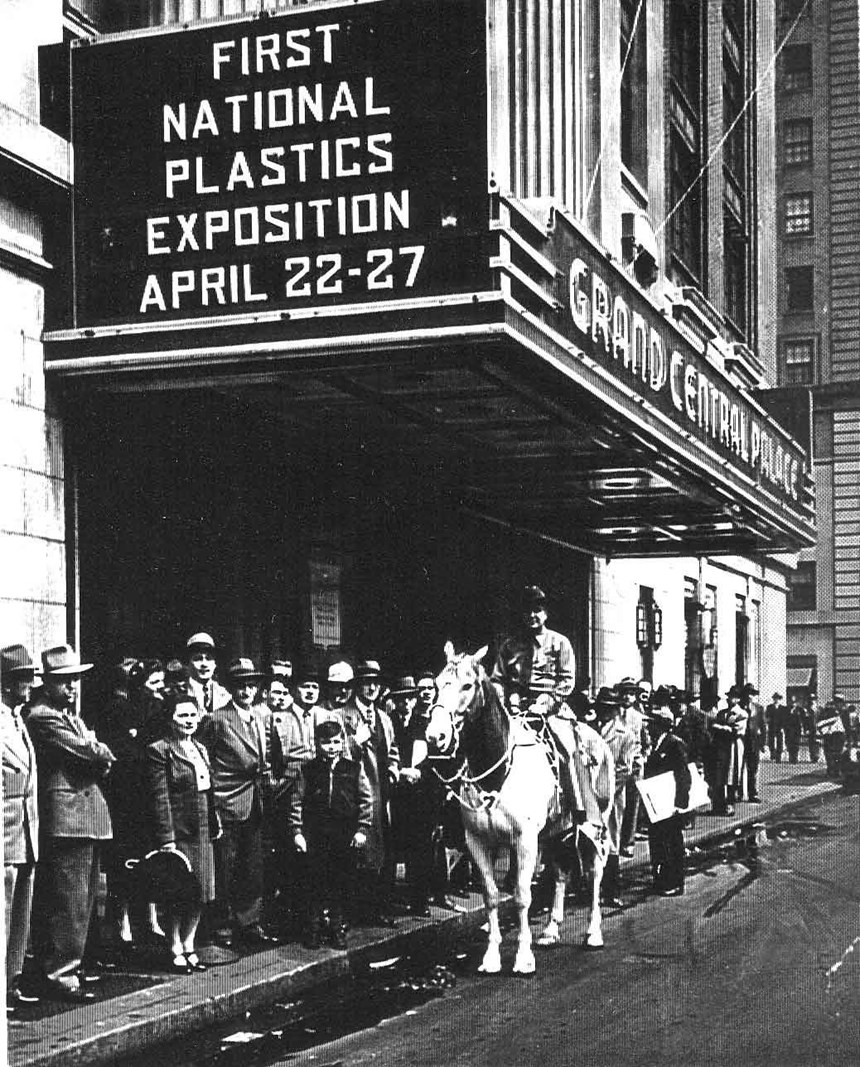

According to Naitove, the very first NPE was in New York City in 1946. There were 164 exhibitors–most of them in 10 x 10 booths–and the show occupied one 24,600 ft2 exhibit hall. Reportedly, 87,000 people showed up. Why so many? The first NPE was open to the general public.

“The place was mobbed, and the fire marshal had to shut the doors,” says Naitove.

When Naitove started coming to NPE in the 1970s, attendance was around 40,000 and has grown to 65,000. There are now more than 2000 exhibitors and the show occupies 1.1 million ft2–a far cry from those early days of the 10 x 10 booths.

So, what was big at NPE in the 1970s?

“Solid state controls, if you can imagine,” says Naitove, “I’m amused to look back and see solid state controls on machines was a news item–I mean as opposed to vacuum tubes. And I remember people touting having a microprocessor on their machines. Now, that’s like saying ‘my machine runs on electricity!’”

“You’ll see a group of people at the show talking about the same thing and the next thing you know, it’s a trend. I guarantee you’re going to find something you didn’t expect–something you weren’t looking for.”

Technology isn’t the only thing that’s changed. Business has become increasingly more global. According to Naitove, the first NPE was composed entirely of U.S. exhibitors. Today, international companies make up at least 40% of exhibitors. “That’s a big change in the industry,” says Naitove, “A lot of consolidation and the fact is that the machine technology for plastics largely comes from abroad today.”

Along with new technologies and new markets come new trends. In the 1980s it was robots. In ‘88, quick mold change systems. In the last decade, medical applications have become a big trend.

“Back then it wasn’t unusual to see a machine standing on the carpet cranking out some parts,” recalls Naitove, “Today companies are promoting what you would call a work cell. There’s a collection of equipment upstream and downstream, automated feeding and blending equipment, a robot’s putting a part on a conveyor or feeding an inspection, assembly or decorating operation–a whole manufacturing system.”

The way exhibitors showcase their products and services has also evolved.

“There’s more wow-factor and showmanship today,” says Naitove, “Some of it is more entertainment-oriented: Wittmann-Battenfeld is famous for showing robots playing basketball and at the last NPE show Star Automation played miniature golf with robots.”

Technology advancements and trends continue to come down the pipeline. Just how much will NPE grow? Looking back at 1946 it sounds like 87,000 is still the number to beat! One thing’s for sure, the plastics industry will continue to grow and evolve. And NPE continues to evolve right along with it.

“A show like this becomes a big pool of information you can draw on for the next few years,” says Naitove. “You’ll see a group of people at the show talking about the same thing and the next thing you know, it’s a trend. I guarantee you’re going to find something you didn’t expect–something you weren’t looking for.”

Related Content

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;width=70;height=70;mode=crop)