Formlabs, an SLA 3D printing company based in Massachusetts has launched two new product offerings at RAPID 2017, Form Wash and Form Cure. The two machines both aim to automate post-processing methods and enable a more streamlined printing procedure with the Form 2.

Dávid Lakatos, Chief Product Officer at Formlabs explains that, “anyone who’s used a 3D printer knows the dirty secret of the process: a lot happens in between hitting ‘print’ and holding a final product.” Addressing this, he explains Formlabs has “developed Form Wash and Form Cure to bridge that missing gap; making it easier than ever to go from finished print to ready-to-use part.”

Automating the post-processing method is also the main focus of PostProcess Technologies, a New York company that just raised $4 million in investment funding.

Form Wash

The Form Wash “offers a uniform, consistent, and automated cleaning process.” According to Formlabs, once the user has loaded in the printed part or Form 2 build platform, a time can be selected and then the machine left to carry out its rinsing process.

Formlabs encourages users to “set the time, and walk away.”

Once left to its own devices, the machine’s impeller agitates parts in isopropyl alcohol. The Form Wash also features a hydrometer that will let the user known when it is time to change out the isopropyl alcohol. Once it has finished its washing process, the machine will raise the basket or platform “to unveil perfectly cleaned parts ready for post-curing.”

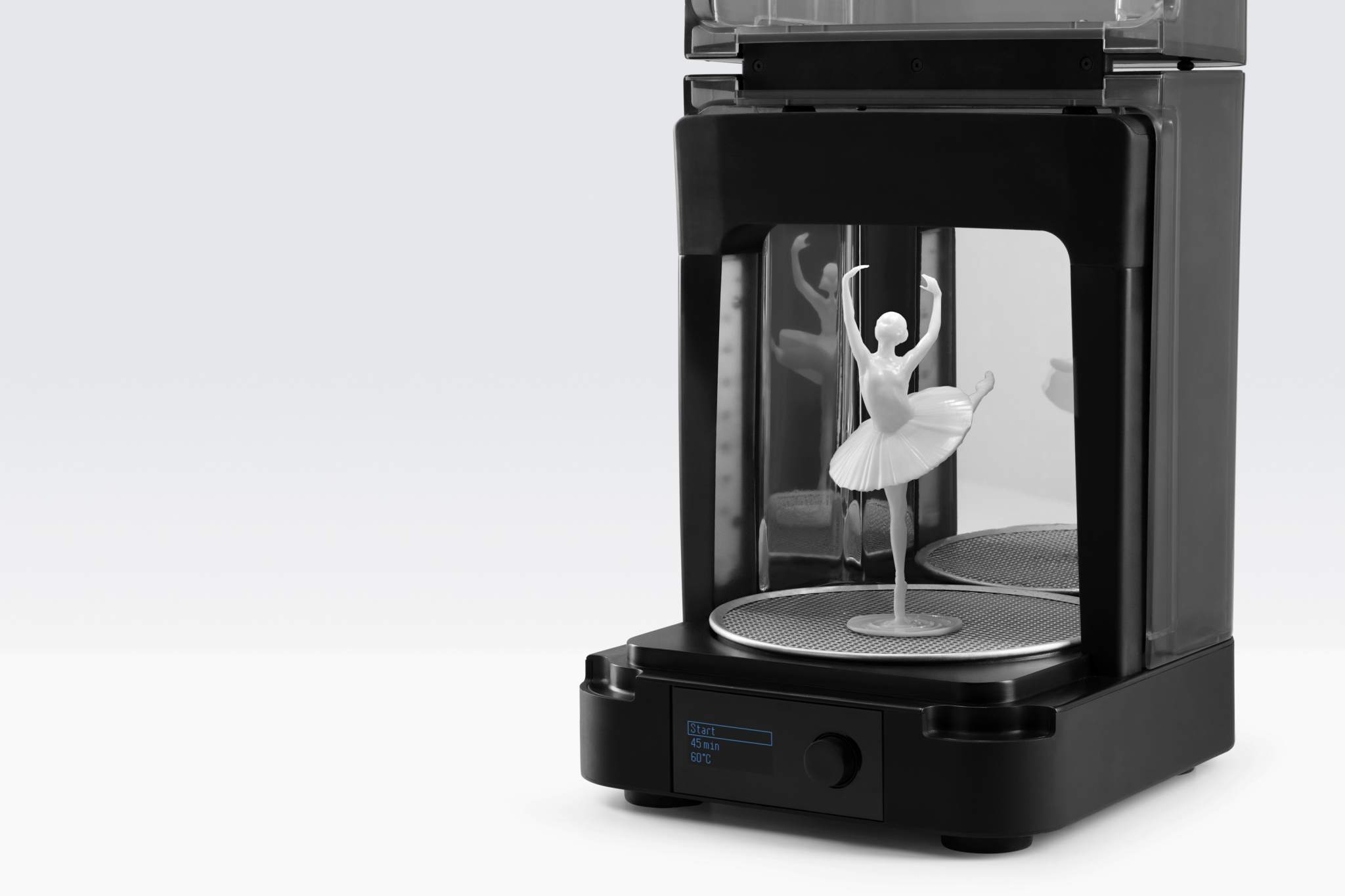

Form Cure

According to Formlabs, the Form Cure machine “introduces a powerful method that enhances post-curing 3D prints by precisely controlling light, temperature, and time.” The machine uses 405 nm light along with a heating system “that achieves temperature conditions ideal for the properties of the SLA printed parts.”

While post-curing is not essential for every resin, Formlabs state that “post-curing with Form Cure improves the performance of all Formlabs materials.” With standard resins there is an increase in strength, “engineering resins reach peak performance, and castable resins burn out more cleanly.” The post-curing process is essential for use of biocompatible resins, such as the recently released dental resins.

Pricing and availability

Formlabs is now taking preorders for the two devices with shipping expected to begin in September 2017.

The Form Wash will be priced at $499; while the Form Cure at $699.

The 3D Printing Industry Awards will be taking place this month in London and voting is still open to decide the winners.

For the latest 3D printer news, subscribe to our newsletter and follow us on twitter.

Featured image shows the Form Cure system. Image via Formlabs.