3D printing has evolved over the last decade from a technology only accessible to big manufacturers to one that is achievable in the home office. It is becoming increasingly more affordable and offers a fast means of product creation. However, the ethics, legalities and moralities of 3D printing are becoming increasingly relevant as the speed of innovation surpasses regulation. Here are 10 forms of 3D printing that demonstrate that 3D printing will become as regular as other forms of manufacturing in the years to come.

1. Bioprinting in Health Science

Researchers at North Carolina’s Wake Forest University have created a 3D bioprinter that can produce organs, tissues and bones that could theoretically be implanted into living humans. Researchers from Wake Forest University have created muscle, bone, and ear structures using plastic-like materials and living cells from humans, rabbits, rats, and mice. Amazingly, the living cells survived the 3D printing process. The researchers also successfully implanted their 3D-printed structures into rodents. If the technology works as well for humans as it does on rodents, doctors may be able to use a patient’s own cells to print them a new bone, muscle, or piece of cartilage one day.

This was proceeded by a printer that was able to print artificial skin. Various cell types were placed in the wells of an actual ink cartridge and a printer was programmed to arrange the cells in a pre-determined order. Currently, researchers are using an adapted version of ink-jet printing technology to enable on-site “printing” of skin for soldiers with life-threatening burns. In this technology, “skin cells would be placed directly into a print cartridge, along with essential materials to support them, and would be printed directly on the soldier’s wound at the site of the wound.”

The notion of a skull implant seems like something out of science fiction but last year doctors in China were able to save the life of a baby with hydrocephalus by 3D printing and implanting a titanium skull in three pieces. 3D printed titanium is strong, lightweight, and can be designed to perfectly fit the patient.

2. Drug Printing

Recently US-based Aprecia Pharmaceuticals released the world’s first 3D printed drug, Spritam, a drug to treat seizures in epileptic patients. The printing comes from MIT produced technology using the company’s trademark ZipDose technology. Produced using technology by sandwiching a powdered form of the drug between liquid materials and bonding them at a microscopic level, the printed pills dissolve rapidly on contact with liquids.

3D drug printing is a huge step towards personalised medicine. Alteration of a pill’s surface area through printing means that the size, dose, appearance and rate of delivery of a drug can be designed to suit an individual. In the future this could mean on-demand drug-printing facilities at clinics, hospitals and pharmacies, or even in patients’ homes.

3. DIY Dentistry

Not surprisingly, dentistry is another industry set to be transformed by 3D printing. Perhaps its biggest disruption of late is that of a 20-year-old college student printing his very own set of clear, orthodontic aligners — just like the ones that sell for thousands of dollars — all for less than US$60. While ostensibly a skill limited to those with access to materials and appropriate knowledge, it demonstrates how 3D printing will make traditional products cheaper.

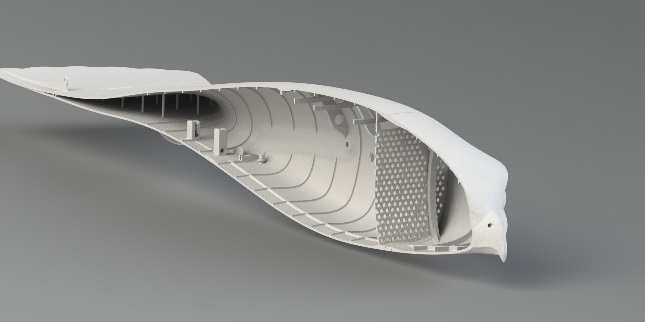

4. Robot Birds

Birds are beautiful creatures. However, they can endanger passenger safety by damaging an aircraft, spreading disease or ruining crops. In response, Dutch company Clear Flight Solutions has created high-tech “Robirds”.

As this article by Materialise explains,

“These remote controlled robotic birds of prey, with the realistic appearance and weight of their living counterparts, serve as modern-day scarecrows. Robirds propel themselves by flapping their wings, with a flight performance comparable to real birds.”

These Robirds can be used at airports, orchards, fields, and waste sites to scare away the real and much peskier birds. They have developed two types of Robirds: the falcon, which can be used to chase off birds up to 3kg, and the eagle to chase away any type of bird.

5. Bicycles

The reality of a 3D bicycle coming to the retail market is limited due to the cost and size of the printer required and various construction challenges. Despite these initial hurdles, the lives of bike riders are being made easier by companies like Bastion Cycles with their 3D printed titanium parts and ETT Industries who are offering 3D printable bike parts that can be printed at home. This is great news for cycling enthusiasts who embrace the promise of new 3D printing technology and want to incorporate it into their own rides.

6. Shoes

The notion of 3D printing of shoes has definite appeal. Who wouldn’t want a custom pair of shoes fitted to their exact measurements? But 3D printed shoes are still limited to either shoe parts or limited editions. New Balance has this week released Zante Generate Running Shoes, the first high-performance running shoe with a full-length 3D printed midsole. Last year, Adidas released a running shoe with a 3D printed midsole, and in March we saw Under Armour release shoes that featured a 3D printed midsole and a 3D upper design that helps provide a precision fit.

Outside of the sports area, shoes seem to be limited to the realm of the highly artistic, such as those high fashion offerings by United Nude shoes. These offerings are printed in the store, right before the customers’ eyes. One other interesting concept is the offerings by Feetz, who 3D print shoes based on photos of your feet.

7. Houses

While it is not possible or practicable to construct an entire house from 3D printing alone, contour crafting shows a way forward. Contour crafting (CC) is a layered fabrication technology developed by Dr. Behrokh Khoshnevis from the University of Southern California. This technology just might revolutionize the construction industry. Using the contour crafting process, “a single house or a colony of houses, each with possibly a different design, may be automatically constructed in a single run, embedded in each house all the conduits for electrical, plumbing and air-conditioning”.

Contour crafting is being touted as a valuable application for emergency, low-income and commercial housing. NASA is even exploring possible applications of contour crafting for building structures on other planets.

8. Drawing

Possibly the funnest example of 3D printing is provided by 3Doodler, a hand-held pen that allows you to “draw” your 3D printed object.

The 3Doodler is often compared to a hot glue gun. You press a button to start, pause and stop the pen. When starting your drawing, you press the tip of the pen onto a flat surface and then draw the 3D object of your imagination in midair!

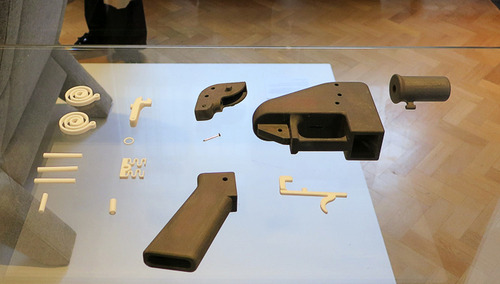

9. Guns

Perhaps the most controversial example of 3D printing is a gun. In 2013, the world’s first 3D printed gun was successfully fired in the US. Invented by Defense Distributed, the gun was almost entirely made up of 3D printed parts in ABS plastic — the firing pin was the only metal (and non-plastic) component. The 3D printed gun’s plans were controversially released for all to access online and were subsequently downloaded 100,000 times in two days. The US government has worked hard to prevent the download and spread of these plans, however, the online release of such material is hard to undo.

10. Changing Lives Through the Building of Prosthetics

3D printed prosthetics are already making an incredible difference to people in need around the world. One example of this is the work of Refugee Open Ware (ROW). They are “a global humanitarian innovation consortium, whose mission is to employ advanced technology to improve human rights fulfillment of both refugees and host communities in conflict-affected areas” (source). ROW provides training to displaced persons and host communities while building solutions to the problems facing victims of conflict. They currently have a fabrication laboratory in Jordan which trains locals to manufacture and create 3D printed prosthetics.

Frequently Asked Questions about 3D Printing Transforming Our Reality

What are some of the most innovative uses of 3D printing in the medical field?

3D printing has revolutionized the medical field in numerous ways. For instance, it has been used to create customized prosthetics and implants, which are tailored to the specific needs of individual patients. This not only improves the comfort and functionality of these devices, but also reduces the time and cost of production. Additionally, 3D printing has been used to produce realistic models of organs and tissues, which can be used for surgical planning and training. In the future, it is hoped that 3D printing will be used to create functional organs for transplantation.

How is 3D printing transforming the automotive industry?

The automotive industry has embraced 3D printing for its ability to rapidly prototype and test new designs. This technology allows manufacturers to create complex parts and components that would be difficult or impossible to produce using traditional manufacturing methods. Furthermore, 3D printing enables the production of lightweight, high-strength materials, which can improve the performance and efficiency of vehicles. Some companies are even experimenting with 3D printing entire cars.

What are the environmental implications of 3D printing?

3D printing has the potential to be more environmentally friendly than traditional manufacturing methods. It is a form of additive manufacturing, which means that it only uses the material necessary to create the object, reducing waste. Additionally, 3D printing can be used to produce items on-demand and locally, reducing the need for long-distance shipping and storage. However, it’s important to note that the environmental impact of 3D printing can vary depending on the materials used and the energy consumption of the printer.

How is 3D printing being used in the construction industry?

In the construction industry, 3D printing is being used to create complex architectural structures, reduce waste, and increase efficiency. For example, it has been used to print concrete walls and other structural elements. This not only speeds up the construction process, but also allows for the creation of designs that would be difficult to achieve with traditional construction methods. In the future, it is expected that 3D printing will be used to create entire buildings.

What are the limitations of 3D printing?

While 3D printing has many advantages, it also has some limitations. For instance, it can be slower than traditional manufacturing methods for large-scale production. Additionally, the quality and strength of 3D printed objects can vary depending on the materials used and the precision of the printer. Furthermore, there are challenges associated with copyright and intellectual property rights, as it is easy to replicate objects using 3D printing.

How is 3D printing changing the fashion industry?

3D printing is transforming the fashion industry by enabling designers to create intricate and unique pieces that would be difficult to produce using traditional methods. It also allows for greater customization, as items can be tailored to the specific measurements and preferences of individual customers. Furthermore, 3D printing can reduce waste by only using the material necessary to create the item.

What is the future of 3D printing?

The future of 3D printing looks promising, with potential applications in a wide range of industries. It is expected that the technology will continue to improve in terms of speed, quality, and cost-effectiveness. Furthermore, it is anticipated that 3D printing will be used to create more complex and functional objects, including electronic devices and biological tissues.

How does 3D printing work?

3D printing works by creating an object layer by layer. The process begins with a digital design, which is sliced into thin layers using specialized software. The printer then builds the object by depositing material layer by layer, following the design instructions. The material, which can be plastic, metal, or even biological cells, is usually deposited in a liquid or semi-liquid state and then solidified.

What materials can be used in 3D printing?

A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, and even biological materials. The choice of material depends on the desired properties of the final object, such as its strength, flexibility, and appearance. Some printers can use multiple materials in a single print, allowing for the creation of objects with complex structures and properties.

How can I get started with 3D printing?

Getting started with 3D printing involves several steps. First, you will need to acquire a 3D printer and the necessary materials. There are many different types of 3D printers available, ranging from inexpensive models for home use to high-end machines for industrial applications. Next, you will need to learn how to create or download digital designs, which can be done using 3D modeling software or online repositories. Finally, you will need to learn how to operate the printer and troubleshoot any issues that arise.

Cate Lawrence

Cate LawrenceCate Lawrence is a Berlin based writer and blogger who spends her spare time cooking and teaching her cat to chase a red dot.